Agar: The Wonder Wood

- By Gargi Sur

- October 13, 2023

A Potential Economic Jewel of North Tripura

The rarest and most expensive wood in the world is agarwood, sometimes referred to as "the wood of the God." For more than 2000 years, people have used agarwood, a fragrant substance derived from the resin of Aquilaria trees, for medicinal, spiritual, and olfactory purposes. This is an essential ingredient in goods like incense sticks, scented cosmetics, and long-lasting scents. The tree, which was once on the verge of extinction, has settled in North-East India. It has one of the fastest rates of growth among evergreen trees. It may thrive when there is a yearly rainfall average of between 2000 and 4000 mm. The temperature should be between 20 and 33 degrees Celsius, and there should be at least 70% humidity. Clay-sandy soil on steep slopes is ideal for it. North Tripura naturally possesses the right environment for the cultivation of agarwood because it is a part of North East India.

Only when aquilaria trees are hurt, wounded, injured, afflicted with a bug or fungus, etc. can they produce agar-oil. The Aquilaria tree produces resin as a protection mechanism. Fewer than 1% of trees are affected by natural infection. Aquilaria growers generally pierce the tree with a number of iron nails in order to purposefully infect the tree. This indicates the tree's ability to fend against pollution from hydrocarbons and metals. Thus, the polluted area's Aquilaria cultivation will be both commercially and environmentally feasible. According to the Agar Association of Tripura, the market for agar stretches back four generations of agar oil extraction. It has existed ever since the Manikya Dynasty. Agartala, the name of Tripura's capital, is derived from the tree. Nearly every family has an Aquilaria garden in the North Tripura regions connected with agar. Due to its low maintenance, low growth input needs, and favourable environmental characteristics, the tree has significant economic potential. A tree with so many different names and the highest demand and price on the international market hasn't yet changed the destiny of the district.

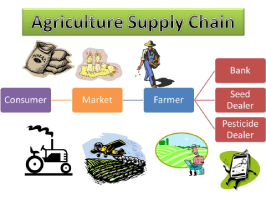

To improve the district's skill, livelihood, and economy, a comprehensive business plan is required to solve the demand-supply mismatch for Agarwood and related products. According to information from the North Tripura Forest Department, there are around 1 crore Agar trees in the 32 villages that have so far been investigated, and the district plants about 2 lakh Agar trees each year.

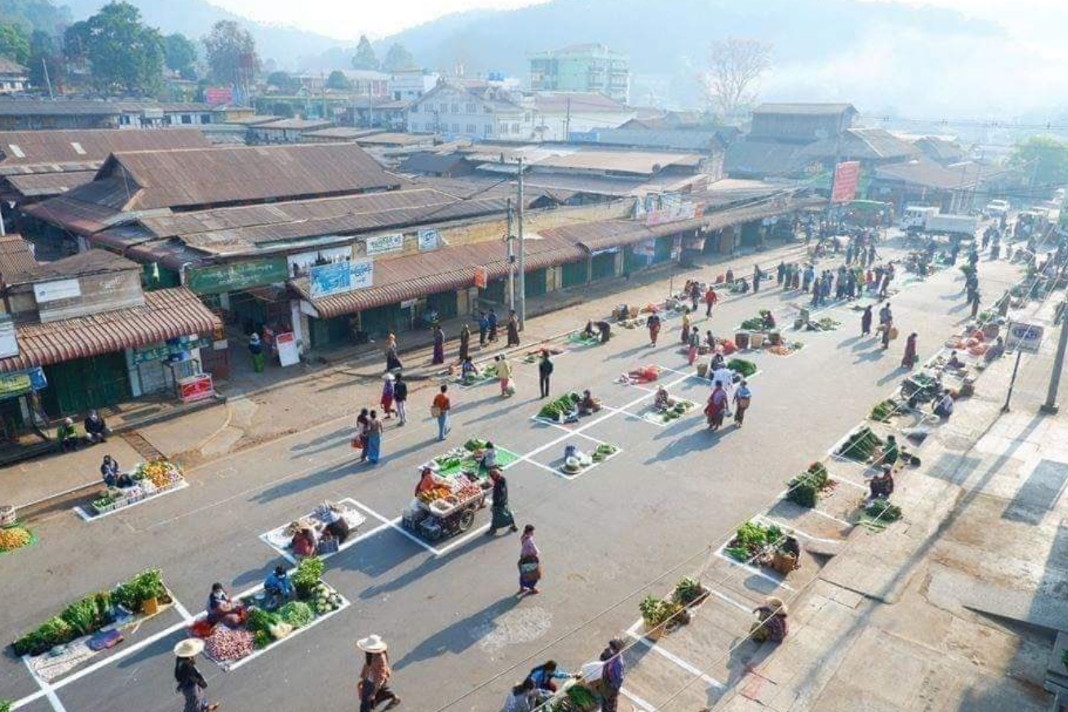

Aquilaria trees may be found inside of around 80% of the residences in the neighbourhood. The Kadamtala block has the most agar plantations, followed by the Kalacherra and Panisagar blocks. The majority of agar comes from Kadamtala in Tripura. In the district, there are 27 licences for agar sales and 7 licensees for agar processing facility establishment. An aquilaria tree can be sold for as low as 5,000 rupees or as much as 1-1.5 lakhs when it has grown fully in 10 years, depending on the grade of the tree.

10,000 agar trees may be produced per hectare of land. The agar trees will grow to their maximum size in ten years. To finish the process, it is now necessary to cut down agar trees and remove the oil and chips from agar. This affects 20000 homes in the region directly or indirectly.

Due to its widespread production and viability as a commercial product, agar-oil is the North Tripura district's ODOP (One District One Product). The Tripura government is also keen to support farmers in their efforts to grow agar for market. According to the Tripura Agar Wood Policy 2021, there should be four times as many agar trees by the year 2025 and agar usage should be encouraged and made legal for businesses with a turnover of Rs. 2,00,00,00,000.

The wood pieces are used for burning and are sold directly to consumers. Since they give off a nice scent, burning wood pieces are frequently kept in homes. The concept is similar to how agarbatti is lit in Hindu houses. Most Middle Eastern countries have a critical need for this.

Chipped wood may soak in water for more than three to four months, depending on its quality. After soaking, the chips are cooked in the boilers. Boiling separates the water and oil. The oil sells for between 6 and 8 lakhs a litre, which is the highest price, depending on the aroma's quality. Even the remaining boiling water is aromatic enough to convince someone to buy. Both water and oil are employed in the production of perfumes. The leftover damaged boiling wood is eventually sun dried and processed into fine powder for making incense sticks.

In Tripura, it takes two people all day to chip an agar tree, whereas in Assam, it just takes two people a few hours. Efficiency and skill are somewhat weak in Tripura. Most young children chose this skill-building activity as their primary source of money, particularly those who attend school or are school leavers. There are no official training facilities or certified teachers available to teach these people. The only source of hope is in the community, but it is not always possible for the members of the Agar Association to invest enough time in educating these children.

Assam is one of Agar's biggest competitors in India. Additionally, Indonesia, Malaysia, Cambodia, Lao DPR, and Papua New Guinea are the region's main export competitors and producers today.

Although the community still passes down these skills from one generation to the next, the National Skill Qualification Framework (NSQF) has recently recognized the processing of agar as a new employment function. For the district's agar industry, this is a positive move. Tripura now has the chance to file for GI tagging for agar in order to get more rapid economic and industrial growth and worldwide recognition.

Gargi Sur